Blog

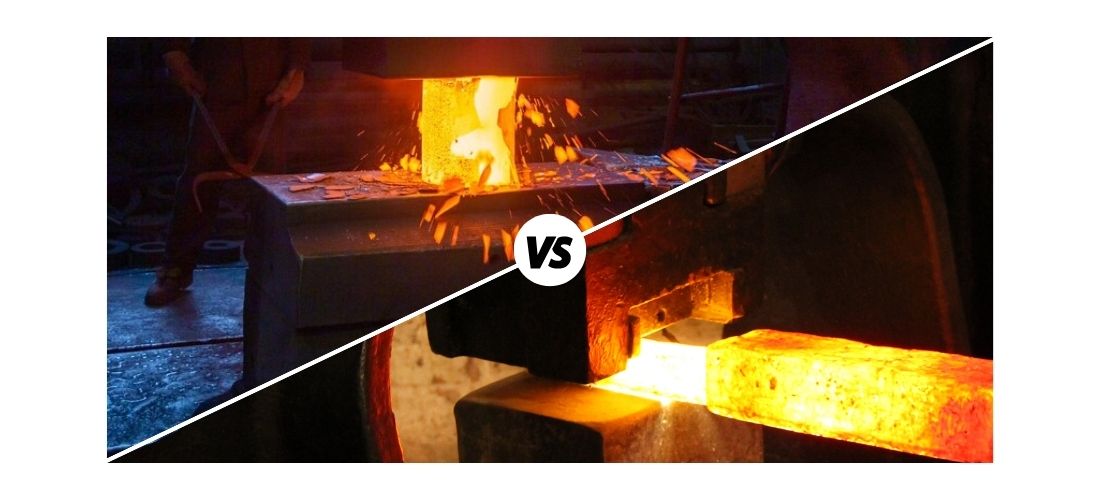

Difference Between Open Die Forging and Closed Die Forging

Open die forging is the process of shaping the metal between two flat dies or anvils. The process is flexible and adaptable and can be applied to many types of workpieces. On the other hand, closed-die forging utilizes intricately shaped dies that define the final shape of the workpiece. It is ideal for highly accurate and complex components with uniform dimensions.

This blog describes every key difference between open die forging and closed die forging.

1. Process

Open Die Forging:

It begins with placing the billet or a metal ingot between two flat dies. The compressive forces are delivered from hammers or presses so that the metal gradually takes the required form.

The manipulations of hand or specific tools may be applied to control and guide the flow of the metal in forging. This process, therefore, implies the use of a very wide range of flexibility when it comes to forming workpieces that ought to have their designs or dimensions altered.

Closed Die Forging:

It entails two heavily machined dies containing complementary cavities that detail the final shape of the closed die forging components with much detail. The metal billet is put in between the two dies, on which the press exerts enormous pressure so that the metal fills the die cavities.

After closing the dies, the metal gets lodged in the cavities, and therefore, there will be an exact copy of the shape of the die. This process is very accurate and reliable. This way, through many repeated operations, parts with repeated properties in dimension and intricate details are obtained.

2. Tooling

Open Die Forging:

Generally, it uses quite simple tooling. These are:

Forging hammers: Impact blows on the metal.

Hydraulic presses: Applying steady, regulated pressure to shape.

Mechanical presses: A combination of impact and steady pressure.

Closed Die Forging:

Usually employs much more advanced and sophisticated tooling. These are:

High-speed presses: High speed and impact.

Hydraulic presses: Ideally suited for those applications that need very precise force and stroke for intricate geometries.

Mechanical presses: One press that can exhibit both speed and force for lots of applications.

3. Applications

Open Die Forging:

General forming: General shaping into rounds, squares, flats, etc.

Pre-forming: Preparation stock for subsequent operation in closed die forgings.

Rebuilding and rehabilitation: Repairing cracked or worn pieces.

Mass production: Large Forgings applied in space heavy mechanical.

Closed Die Forging:

It is applied to the following:

Mass Production: High volume production producing many identical copies in a huge batch.

Complex Geometric: making large complex geometry using high dimensional precision and tolerance and strength parts that require extraordinary resilience and toughness to be created.

Mechanical presses: creating other components, transmission, engine automotive forging parts, etc.

4. Benefits

Open Die Forging:

Flexibility: The process allows for changes in the design and modification of the product, which can be achieved at the forging stage.

Low cost of tooling: It involves low-cost tooling compared to closed-die forging.

Most suitable for low-volume production: It is economically feasible for low-volume runs.

Closed Die Forging:

High accuracy: It delivers good precision and quality consistency.

Excellent surface finish: It may provide a very smooth and consistent surface.

High strength and toughness: It improves the mechanical properties of the forging made.

High-speed production: It provides high-speed and high-volume manufacturing of the same part.

5. Disadvantages

Open Die Forging:

Low dimensional accuracy: It may have more dimensional deviation than the closed-die forging.

Less complex: Complex shapes and details are difficult to achieve.

Lower production rates: Usually slower than the closed die forging.

Closed Die Forging:

Heavy tooling costs: It requires a lot of time to design and make complex dies.

Rigidity: It is not an easy task to implement design changes once the dies are made.

Higher setup costs: It wastes a large amount of time and laborto set up the forging process.

6. Material Considerations

Open Die Forging:

Recommended for a range of metals such as:

-> Steel

-> Aluminium

-> Copper

-> Titanium

Closed Die Forging:

Best suited to the ductile material that can easily flow under pressure. Most common application:

-> Carbon Steel

-> Alloy Steel

-> Stainless Steel

7. Cost

Open Die Forging:

Easier to be economical on small lot sizes and simple designs.

Closed Die Forging:

Easier to become economical on higher lot sizes and more complex shapes. However, initial tooling expenses may be a bit high.

8. Environmental Impact

Open Die Forging:

Generally, it has a low environmental impact due to simple tooling and relatively less energy consumed.

Closed Die Forging:

This kind of forging would be more energy intensive in comparison to the energy that is required to make the die and perhaps scrap that might be generated.

Conclusion

The difference between open die forging and closed die forging usually depends on several factors that would involve form, how many are to be produced, the precision accuracy needed, and budget. Open-die forging can accommodate open changes of any number of shapes, but the closed-forging technique offers excellent precision at very high production rates. Appropriate consideration of these facts would enable producers to choose an appropriate forging method best suited to their requirements and, hence, guarantee the best output.

Read more: An Ultimate Guide to Closed Die Forging Components